Handgonne

Faustbüchse

When writing about these very early firearms, I use the rather unusual word "handgonnes", since it appears to me, that there is no appropriate word in modern English to describe this kind of weapon. I don't like to use "handguns" because this word is used today for modern rifles and shotguns. "Gonne" is the Middle English word for "gun" and was actually used in the 14th and 15th century to describe these contemporary types of guns. By the way, in German they are called "Faustrohr" or "Faustbüchse" (=fist pipe or fist box) which distinguishes them from any other firearm.

Black powder seems to have been invented in Europe in the first half of the 13th century by an unknown alchemist. The first dated recipe was given in 1265 by Roger Bacon, a British Franciscan friar and former professor of philosophy at the University of Paris. (Opus Tertium, dedicated to Pope Clemet IV). Here, we learn that black powder was first used to make firecrackers by young villains to scare innocent citizens at night. Roger Bacon didn't mention guns.

The first and oldest picture of a firearm comes from Walter de Millimete (De Notabilitatibus Sapientis et Prudentia Regnum, 1326), look page "History". The picture there shows a small cannon fixed to a table, firing an arrow with a shaft the size of the gunner's forearm. It is hard to believe that the inventor of firearms had cast a large cannon barrel for his first test. I think he probably first built a model of it, and that model would become a handgonne. The use of an arrow as a projectile doesn't seem too far fetched. After all, this was the kind of projectiles used for thousands of years.

|

||||

| Fig. 1: The siege of a castle. Painting by Qinte Curce, 1468. Painting stored in the archives of the British museum, London. |

||||

This picture above shows us handgonners and archers in action, side by side. From this picture I learned how to hold handgonnes the proper way for testing them.

The Tannenberg Handgonne

The so-called "Tannenberg-handgonne" was the very first handgonne that I held in my hands. It is on display at the Germanic Museum Nuremberg (Germany) and fascinated me instantly. It was found at an archeological excavation in 1849 at the bottom of the water well of the Tannenberg castle in Hessen. When found, this handgonne was still loaded with a lead bullet.

That gonne was a gift from the Duke of Hessen to the Nuremberg Museum. But the bullet and the excavation documents are still with the archaelocical service of Kassel (Hessen). The bullet appeares to be cast with a filed off sprue.

| Fig 2: The original Tannenberg gonne as it is displayed in the Germanic Museum in Nuremberg today. | |||

The Tannenberg castle was destroyed in 1399. So, you can safely assume the gonne is older than that. And also of importance: It was loaded with a leaden bullet and not with an arrow.

It has been questioned whether the dimple around the touch hole is caused by corrosion only or if it was made purposely as a flash pan.

To test that firearm, I copied it as exactly as possible. The original is cast from bronce. So I made my copy from so called "cannon bronce" (88Cu12Sn) on my lathe and gave it the final shape by filing. Here it is! It is stocked atop an octagonal to round ash staff.

|

||||

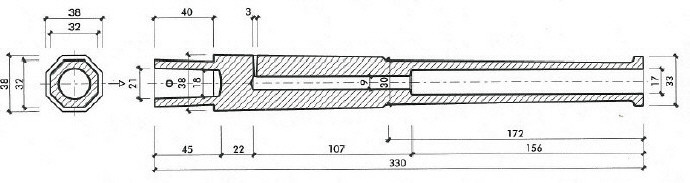

| Fig. 3: It is difficult to draw the original Tannenberg-gonne exactly. Due to casting and corrosion you have to allow at least ± 1 millimeter. Total length of the octagonal gonne is 330 mm (~1 foot). Caliber is 17 mm. Caliber of the Chamber is 9 mm. The shape of the octagonal barrel appears somewhat erratic. The breadth of the eight faces, seen from the breech and counted clockwise are: top=16mm, 1=14mm, 2=12.7mm, 3=13mm, 4=14mm, 5=13.5mm, 6=12.5mm, 8=14.5mm. |

||||

The peculiar powder chamber of the gun is remarkable. At a first glance, you would think it is a safety measure to avoid the explosion of the gun. But according to the contemporary literature, the gunsmiths did it for better performance. They believed, the expanding gas acts predominantly on the center of the bullet. And in a cylindrical barrel, the gas pressure would act predominantly on the tilted flanks of the round bullet, where the gas wouldn't act as efficiently as towards the center of the bullet.

As I will prove later, the gunsmiths were right, but their explanation was wrong. The hydrostatic paradox of modern physics wasn't known then.

Modern cylindrical version of the Tannenberg-gun

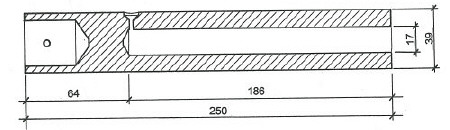

To confirm the experiences of the mediaeval gunsmiths and to investigate the effects of the long, narrow powder chamber, I built a cylindrical, modern version of the Tannenberg gun.

| Fig. 4: Cylindrical version of the Tannenberg-gun for testing of the influence of the absent powder chamber. | ||||

|

||||

I made the modern version of the Tannenberg gun from common construction steel St37 on my lathe. To get an identical passage for the bullet, I took into account the volume of the peculiar Tannenberg powder chamber of 6.8 ml. Applied to the 17 mm-bore, it will consume a length of 30 mm from the barrel. Hence I drilled a comparable barrel length of 186 mm.

Be surprised of what came out!

The Danziger Handgonne

The second handgonne I'm going to discuss, is called "Danziger handgonne" because it was found in the city of Danzig, then in eastern Germany , today called Gdansk in Poland. It was found about 1920 by the supervisor of the water supply of the city of Danzig while digging trenches for a new water supply pipe. This supervisor was the the father in law of the present owner.

In the 1970s, a friend of mine had cast 20 bronze copies of this beautiful handgonne and sold them at a moderate price.

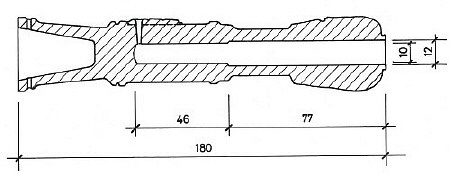

| Fig 5: A relatively small hexagonal handgonne from bronze. The muzzle cone consists of three solemn looking, bearded faces, who surround the muzzle. The touch hole for inserting the fuse is formed by the mouth of a mask. |

||||

|

||||

This handgonne also has a large powder chamber, but the difference between the bores of the barrel (12 mm) and the powder chamber (10 mm) is not as striking as that of the Tannenberg gun. The powder chamber is relatively long, 37% of the total barrel length. The powder chambers of modern 19th century muzzle loaders have powder chambers of only 5 to 10% of the total barrel length.

I assume the powder chamber was entirely filled up by the charge. That would make a very hefty load. If filled with modern black powder, only a small part of the charge would burn up while accelerating the bullet inside the gun. Most powder would burn in front of the muzzle in a huge fire blast. So what was the purpose of these large powder chambers in these old handgonnes?

I have stocked this gonne with a hexagonal, conical cane and added a matching foot from the same bronze. So I can use this handgonne as a walking cane, which I do increasingly indeed, due to my advancing age.

Measurement of the Bullet Velocity and Bullet Energy

with the Ballistic Pendulum

Today it's easy to measure the velocity and the energy of a bullet. You simply buy a chronograph that records the time it takes the shadow of the bullet to pass two photo cells and then, as a result, the instrument displays the velocity on its panel. According to Newton, the bullet-energy then is calculated:

Energy (Joule) = m/2 * V2

where m = mass of bullet (kg) and V = velocity (m/s)

But this method is tricky with black powder muzzle loaders. The bullet may be surpassed by its patch or un-burnt powder residue. What you actually measure then is the speed of the patch. So always keep a safe space between the muzzle and the chronometer.

For saveing money and eliminate missreadings caused by debris, the author chose this ballistic pendulum:

|

|||

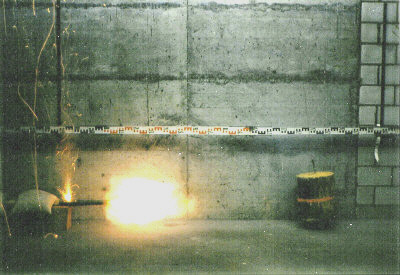

| Fig. 6: The Tannenberg gonne, test-firing at author's ballistic pendulum. The red tape around the wooden block faciliates aiming at the center of the block. By this, possible wobbling of the block is suppressed. Note the horizontal meterstick at the wall for measuring the swing (amplitude) of the pendulum. |

|||

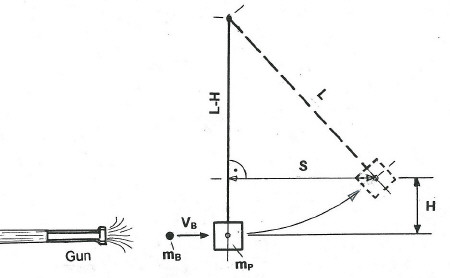

The muzzle velocity and the bullet energy are calculated according to the next draft-sheet.

| Fig.6: ...Legend VB..Velocity of bullet (m/s) mB..Mass of bullet (kg) mP..Mass of pendulum block (kg) H.....Higth of lift (m) S.....Swing of the pendulum (m) L......Length of the pendulum (m) G......Earth gravity (m kg/s2) |

|

|

| Then the equation to calculate the velocity of the bullet VB (or any projectile) is: |  |

||||

|

(m/s)

|

|||||

The secret of the peculiar powder chambers

Since you, dear reader, are now familiar with the determination of the speed and energy of a bullet the old way, I will reveal the results of my handgonne-tests I did in the 1980s.

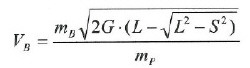

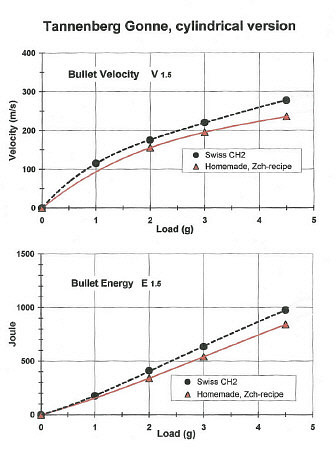

Below, you'll find two diagrams. The left one shows the results obtained with the my Tannenberg-gun (Fig. 2), the results in the right one were obtained with a corresponding handgonne without a powder chamber (Fig. 3). If the latter is loaded with the amount of powder, necessary to fully fill the powder chamber of the Tannenberg gonne (6.8 ml), the same active barrel length remains in the modern, cylindrical gonne as in the Tannenberg-replica. That ensures compareable coditions.

|

|

||||

| Diagram 1 | Diagram 2 | ||||

The two handgonnes were tested with homemade powder (red curves) consisting of 100 parts Saltpeter, 18 parts charred willow wood and 16 parts of sulfur, and with Swiss factory powder grade 2 (black curves). The charge was increased step by step in increments of one of gram powder. With 4.5 grams of homemade powder, the Tannenberg chamber was entirely filled up. Three shots were fired on each load and then the average velocity was calculated.

After this, the type of gonne and the kind of black powder can be distinguished by the following:

| Tannenberg, with powder chamber | Cylindrical bore (not historic) |

| A progressive increase of bullet energy with homemade powder. |

Nearly linear increase of bullet energy with homemade powder. |

| A very slight, progressive increase of energy with Swiss factory powder. |

An absolute linear increase of energy with Swiss factory powder |

| Homemade powder performed signifi- canly better than factory powder. |

Factory powder beat homemade powder by a margin. Neither powder performs as well as in the Tannenberg gonne. |

So, what caused the significantly better performance of the homemade powder in the Tannenberg-gonne? I got the idea of a possible reason by merely listening to the sound of the muzzle blasts. When fired with factory-made powder, both gonnes created the typical "black powder boom".

The Tannenberg gonne, fired with homemade powder, sounds quite different -, a very sharp crack, comparable to a modern gun firing nitro-powder.

I think the cause of this effect is comparable to the knocking of car motors, running on low octane gasoline. When the black powder inside the long powder chamber first catches fire at the touch hole side of the chamber and then starts to burn like a fuse through the long chamber, this causes a sudden increase of pressure with an adiabatic heating of all the air inside the porous homemade powder. As soon as the temperature inside the powder surpasses 300 °C by adiabatic heating, a second fire front is created. So we see a simultaneous ignition of all the black powder inside the chamber! That causes the atypical explosion of the black powder inside the chamber.

Since modern, factory-made black powder is very compact without any air-pores inside the grains, there is no adiabatic heating of air inside the powder grains and, hence, a second firefront is hardly created in the chamber.

According to the contemporary literature, the old gunsmiths observed this, too. They attributed it to the centered push of the gas, the chamber directed towards the center of the bullet. They didn't know anything about adiabatic compression.

How to Shoot the Handgonne?

Usually early handgonnes didn't have powder pans. From the many I have seen, there were only about two or three equipped with a kind of pan which could be closed by a pivoted cover; plus one with a dove tailed sliding cover (Otepaa gonne, Estonia). So, as a rule, most handgonnes have touch holes for ignition only and nothing else.

To a "modern" muzzle loader shooter like me, who is familiar with match lock muskets and flinters, that brings up the question: How were handgonnes ignited? According to the modern literature about ancient armes, two methods are suggested:

1st ...Ignition by a red hot poker wire (German: "Loseisen"),

2nd.. Ignition by a fuse.

Ignition by a glowing poker wire:

That implies you have an open fire at hand. According to the literature, defenders of a fortification kindled a coal fire in a kettle, staked with a number of pokers. I tested this. I bent a three millimeter wire into the shape of a poker iron and heated it red hot by means of a propane gas torch. Woom, - it worked immediately, though I had to hurry to ignite my gonne since the poker cooled rapidly. But after the bang had died away, my poker was bent like a trodden worm. It was not possible to use it a second time. The reason was the recoil of the gonne while the wire was inserted in the touch hole, faciliated by the heat-softened iron.

| Fig 7: Poker wire before ignition of the gonne |

||||

| Fig 8: The bent poker after firing one shot |

||||

Maybe, this method would have worked if the gonne had been hooked to a window sill or a battlement. But this method certainly is not suitable for shooting a hand gonne offhand.

Not by one of those ubiquitous match-sticks of course, but by a slowly smoldering match cord. (The English word "match" derives from the French word "mèche" which means exactly and exclusively this smoldering cord. (The English confuse the two.) But if there is no pan for priming powder, it seems reasonable that gonnes were ignited by means of a fuse. And you will notice exactly such fuses on the Chinese picture, Fig 14, at the end of this page called "three shot gonne".

| Fig.9: Here it is demonstrated how to aim and ignite a handgonne offhand best. Watch the fuse, looking horizontally to the right side. Since you have to concentrate on aiming, you watch the fuse by a glance and hit it easily with your match. Triggering the charge is a matter of half a second then. |

||||

Matches were the only readily available source of fire that could be carried all day long by a traveler, usually stored in a match box, - a perforated tin can worn at the belt. (German: Luntenberger)

The match used here, the kind I usually use in match lock competitions, is a cord woven from hemp, with a 6 millimeter diameter. The match cord is bucked and then impregnated by lead acetate as a catalyst and burns very slowly, - 15 to 17 centimeters per hour. (Look section: Making a Proper Match) The little bit of match you see pinched atop of a split stick would be consumed in no less than in half an hour.

Aiming and Hitting

Remember, neither the Assyrian nor the medieval English archers used any kind of sights on their bows. Intuition was their principle. This is confirmed by modern bow-hunters who easily and consistently can hit a deer at 25 strides distance, be it in flat or sloping terrain, without sights. From my experience, two points are essential for bows as well as handgonnes:

1st: Don't align the gonne too close to the peering line eye/target. I think holding it under the armpit is best. Breast high may also be O.K. Keep both eyes open. In this position your two eyes will send a three dimensional picture to your brain which will "compute" automatically the proper direction of the gonne. (Fig. 8 and 9)

2nd: Don't point the gonne just in the general direction of your goal, be it a card board target or a deer. Concentrate on the very exact spot you want to hit on the target. E.g. don't aim at the whole deer, but precisely at its shoulder. Be relaxed.

| Fig 10: Shooting at a Swiss Army E-target, 25 strides away. |

||||

| Fig. 11: As demonstrated here, the Swiss army E-Target used represents a full size, upright man. I can hit it more or less consistently over this given distance of 25 strides, although, among five rounds fired, one will probably be a miss. A bit more practice would be an asset. |

|||

How effective were handgonnes?

History books about early firearms, written by ignorant historians, as a rule, state that the effect of early handgonne led more to flabbergasting the enemy by smoke and bang, then to really harm him. This is definitely not true. To contradict the historians, I run some tests with steel plates from 1.0 - 1.5 and 2.0 millimeter thickness. Steel quality was steel 37 (St37). This is a low carbon steel, today widely used for construction work like girders or garden fences. Though it can't be hardened, it's a tough steel.

| Fig. 12-13: The performance of the Tannenberg gonne with 4.5 g powder behind a patched 16.8 mm round ball, and The performance of the Danziger gonne with 3.0 g powder and a patched 11.8 mm round ball. The bullets were fired from a distance of two meters. The dents in the steel plates are witnessing tests with more moderate loads. |

||||

Certainly, medieval personal armor was made from hardened steel. But due to its weight, it was hardly possible to wear two millimeter armor.

As I could prove, it is easily possible to pierce steel 37 of considerable thickness with my primitive, homemade black powder.

- With the Tannenberg gonne, with fully loaded chamber (4.5 g powder) = 2.0 mm Steel

- With the little Danziger gonne, fully loaded chamber (3.0 g powder)..... = 1.5 mm Steel

To sum up: The advance of firearms, beginning with the handgonne, changed warfare at the end of the 14th century entirely. Handgonnes were to be taken seriously. From then on, a simple peasant could beat a well-armored knight with the tip of his finger.

And the Chinese?

As a dessert to my findings about the handgonne, I introduce three pictures I found in a copy of Wu Pei Chih (1628). By this date, handgonnes were long outdated in Europe. There it was the time of the 30-years-war that was fought with match lock muskets. The following three Chinese pictures show possible ways to enhance the fire power of the handgonne, - a topic still pursued today.

Last updated: Sept. 2009